2/1/2013

This client was studying in French Guyana for his masters thesis. Miners in the area paid him in gold for bananas he was growing. He used it to create a pair of wedding rings as a gift for his best friend's wedding.

|

High quality gold mined from French Guyana. Mercury is used by small scale miners

|

|

We heated the nuggets under a vacuum hood to evaporate any mercury from the

|

|

The nuggets are melted separately in case one or more contain impurities that inhibit workability. Substantial

|

|

The gold buttons are smashed into pancakes to test malleability.

|

|

Gold, silver, and copper are measured out to melt into an 18k alloy.

|

|

A gold ingot is poured from the melt.

|

|

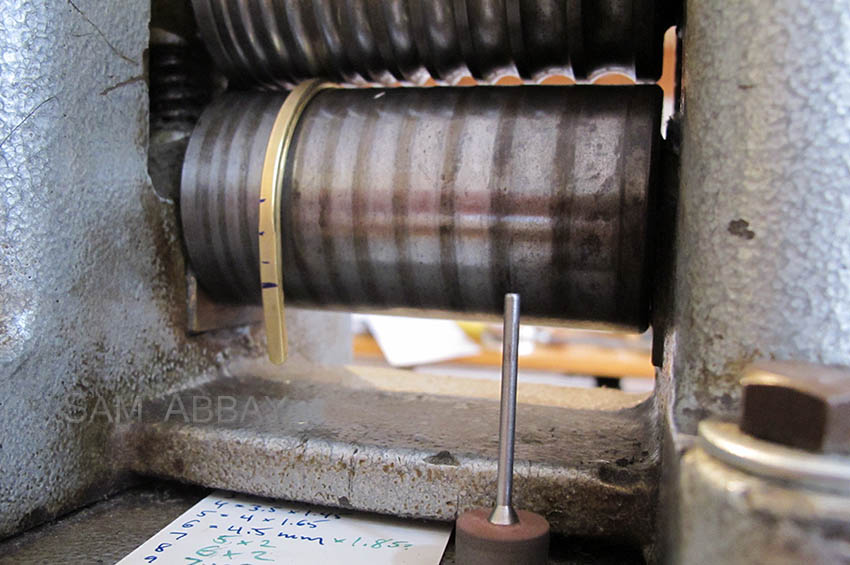

The gold is formed into half-round ring stock in an old Italian rolling mill.

|

|

Gold wire is pulled through a drawplate to create the smaller ring stock.

|

|

The gold ring stock is bent into a circle and with the ends aligned in a tight joint.

|

|

A second alloy of gold with a slightly lower melting temperature fills the seam.

|

|

Excess gold is filed from the joint to create a smooth seam undetectable to

|

|

The completed 18k gold wedding rings with matte finish.

|

Back to classes page -or- alloy workshop pricing.

© 2019 Sam Abbay - New York Wedding Ring dba Sam Abbay

|