8/5/2013

After nearly seven years as a professional goldsmith and metal arts teacher, it was time to make an engagement ring for my own girlfriend.

I started out with a budget - in dollars and time. Mass produced engagement rings can take under one hour of labor. When I teach engagement ring making classes, a basic solitaire takes 10-12 hours. The most complicated engagement ring a customer has made took 40 hours. I figured I could spend up to 100.

I started with a little research about what other DIY romantics who have crafted their own engagement rings made. I was impressed. People with almost no prior experience made beautiful rings, some creative rings, and the documentation was excellent.

Of course, I have the tools and know-how to make an engagement ring, and had already come up with a few ideas that were exciting to me. I put my thinking cap on for a full 50 hours of research before getting my hands dirty - and stopping occasionally to take a photo. Here is how I made my fiancée's engagement ring:

Part I: Refining

|

Here is an example of a tree-of life brooch, which my girlfriend had inherited from

her

|

|

Unfortunately, there are many alloys of gold. This one was made specifically to flow

|

|

As I roll it further, the cracks become worse.

|

|

Now it's a flower.

|

|

Here's our cracked gold ingot again. I will now quarter the gold: mix it with alloy

|

|

The gold and silver are melted in a crucible.

|

|

The ingot is hammered to flatten and strengthen it a bit.

|

|

The resulting mostly-silver ingot is soft and ready to be rolled into a thin strip.

|

|

The rolling mill (far left), rolls it thinner and longer, increasing the surface

|

|

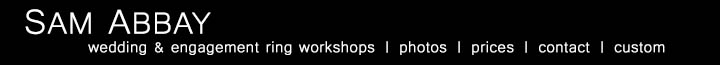

The thin strip of rolled gold in a beaker. Nitric acid will not dissolve

|

|

We have a fierce reaction shortly after the nitric acid is added. The nitric will

|

|

The result is flakes of high karat gold, with a tiny bit of silver that the nitric

|

|

The aqua regia contains Grandma's gold. A small amount of silver chloride can

|

|

The gold is precipitated out with ferrous sulfate.

|

|

Pure gold settles to the bottom of the beaker.

|

|

The gold precipitate is melted together into nuggets.

|

|

After more hours than I would like to admit, three beautiful former-tree-of-life

|

Part II: Plasma

|

|

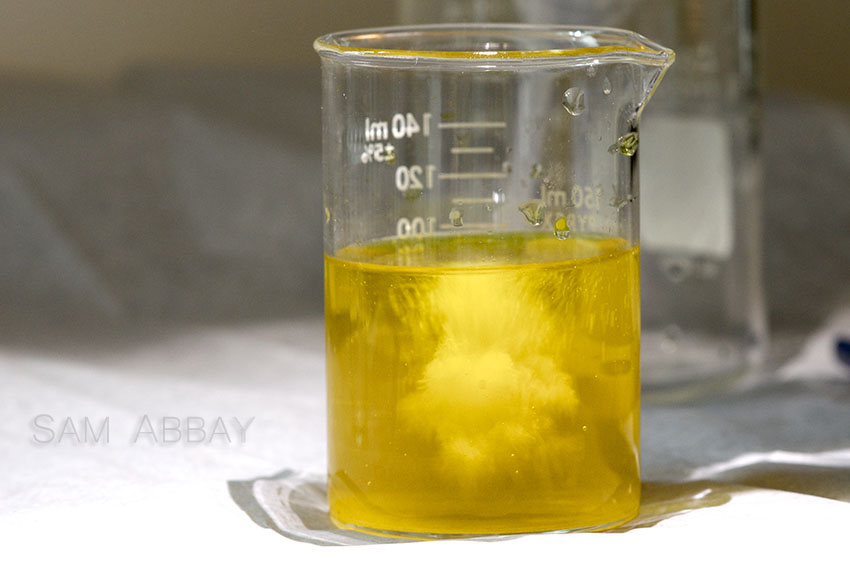

This is a plasma arc speaker.

The purple plasma in the photo is actually playing music.

|

|

Most plasma speakers arc off of a copper surface. I tested a couple dozen alloys

to

|

Here is a video of one of those such tests. Mouse over and click play. Much is

|

|

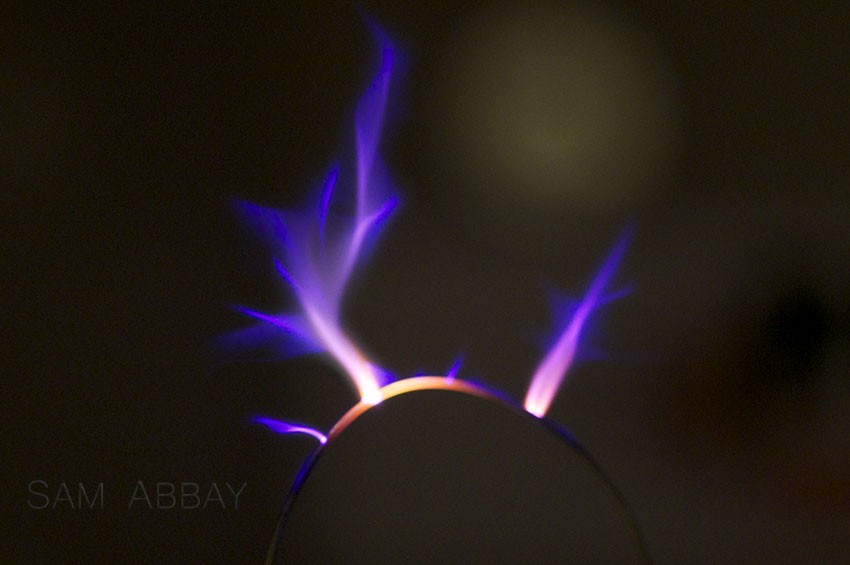

I draw some of grandma's gold engagement ring alloy into wire for testing. |

|

A tiny test ring fits in the speaker...

|

|

Now I test a demo engagement ring with a Moissanite stone, which does not crack from the heat. If the

|

Part III: Construction

|

|

Remember the gold? Time to melt, pour an ingot, and mill it into the parts I will

|

|

Here is a square gold rod, some bezel strip, and a second bezel that I have

|

|

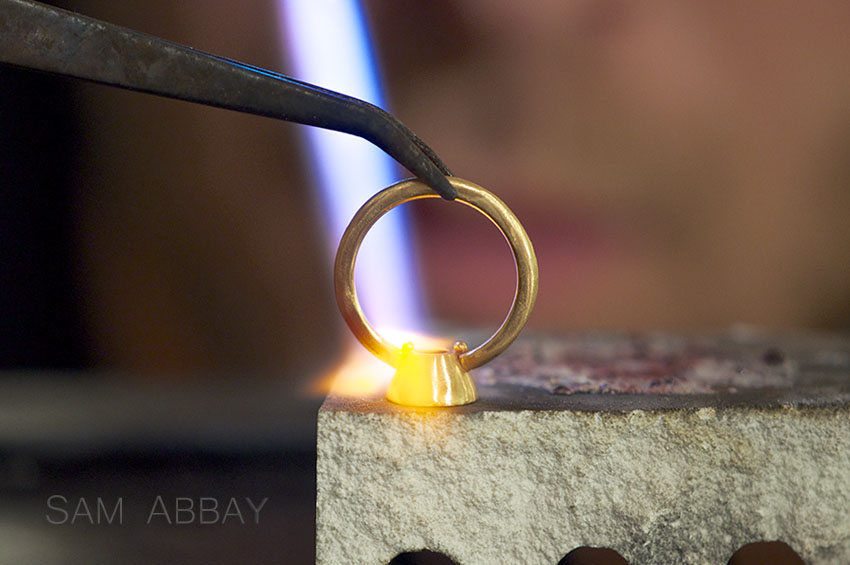

A special alloy of gold designed to melt at a lower temperature is placed over the seam.

|

|

The ring is heated until the solder melts. Capillary action draws the liquid gold

|

|

Gold filings are everywhere as the gold ring is shaped. The ring will now be cut open

|

|

The head is now soldered on to form a complete ring mounting.

|

|

Here is the centerpiece - an antique Old European cut diamond. This cut features

|

|

Using a microscope, I carefully fold the gold bezel over the diamonds.

|

Part IV: Finished!

|

|

Stacking engagement rings! One antique Old European cut diamond and one

|

|

The finished diamond ring as the substrate for the plasma speaker. I recorded a

|

|

The End!

© 2019 Sam Abbay - New York Wedding Ring dba Sam Abbay |